'HERSTRIDES': Cane Design for Women

ENGN 620 Design Briefing - May 20, 2025

This user-centered project uses clinical research, user testing, and iterative prototyping to develop a walking cane specifically tailored for women and minorities, addressing ergonomic improvements, wrist support, and personalization to reduce stigma and enhance the user experience which has long been neglected.

In a team of three, I took the lead role in technical development. I contributed to both primary and secondary research, created all prototypes using foam core and CAD modeling, completed the SolidWorks technical drawings, and performed the engineering analysis.

Problem Statement

Despite accounting for nearly one in five U.S. adults, arthritis remains underserved by current assistive device design—particularly for women, who are 20% more likely than men to experience the condition. While women use mobility devices compared to men, with a 19–29% difference depending on the age group, women are 20% less likely to transition from unmet need to use.

Despite this high usage, the market for walking canes remains largely gender-neutral or male-oriented, with limited options designed for women's unique biomechanics, anatomy and lifestyle preferences. Existing walking canes often ignore the ergonomic needs of women, resulting in products that are uncomfortable, stigmatizing, or poorly suited to their anatomy.

This project addresses the lack of inclusive, user-centered mobility aids by focusing on ergonomic grip design, personalization, and stigma reduction for women with arthritis.

Ideation

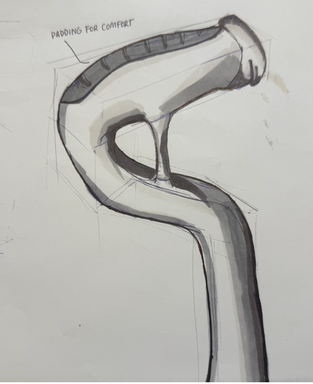

We mapped human, environmental, and engineering factors to define testing goals. Early sketching explored different ergonomic grip forms designed to reduce wrist strain, especially for smaller hands and users with arthritis.

Iterative Process

Each prototyping iteration was improved based on engineering analysis, user research, or feedback from faculty from the Departments of Engineering and our client Dr. Linda Resnik, a medical expert in rehabilitation and professor at the School of Public Health, as well as elderly users at Wingate Residence.

Low-Fidelity Prototyping

Across twelve low-fidelity mockups, we explored variations in grip shapes that could accommodate multiple holding styles, and different wrist and finger orientation to reduce strain and required grip strength.

High-Fidelity

Prototyping

Using CAD software, we developed multiple 3D iterations and 3D printed three cane grip prototypes to test our digital designs, and finally narrowed it down to two grips, that we tested with residents at Windgate residence. The designs vary in thickness and curvature to accommodate different holding styles and promote a neutral wrist position.

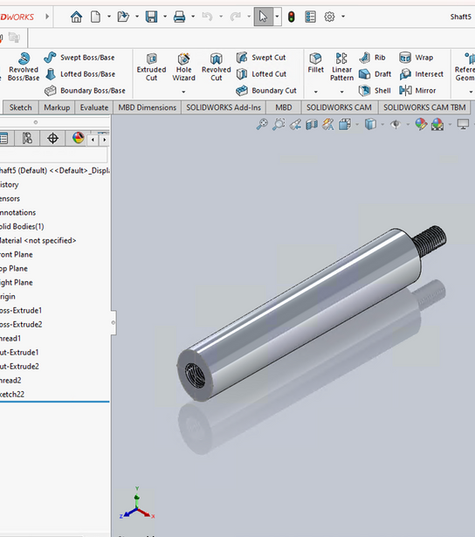

For the cane shaft, we explored designs using 3D-printed models, wood, and a removable fabric sleeve. Initial iterations of the 3D printed cane shaft were composed of five CAD components and featured a screwing mechanism intended to connect the shaft segments. Due to material constraints, the original screwing mechanism was replaced with a dovetail-like joint system, and the end of the shaft was dimensioned to be narrow enough to accommodate a standard cane tip. For aesthetics, we introduced a slight taper (1°) on each shaft segment.

User Testing

Our Advisor Dr. Ted Morse and faculty from the Departments of Engineering helped shape the scope and direction of the project. Our first session with Dr. Resnik helped validate the broader need for our project and confirmed that gender-specific mobility devices remain largely underserved in both research and the consumer market. During our second session, we presented our pink foam grip prototypes. Dr. Resnik helped us narrow down our designs by evaluating them based on comfort, flexibility in hand positioning, wrist alignment, and stability.

On April 23, 2025, we visited Wingate Residence in Providence to meet with 10-16, primarily female, residents aged between 65-80 for an hour-long user testing session. We divided the group into two smaller groups of 5-8 and two facilitators led the conversation using interview guides for their respective group and presented two grip prototypes to get specific feedback.

Testing Results

Grip D

Grip A

Our feedback at Wingate Residence informed meaningful adjustments to material, overall grip design, diameter, handle curvature, textures. and wrist orientation.

User testing revealed a slight preference for one of our grip designs—Grip A, over the other triangular grip—Grip D. When asked what participants liked specifically about the A grip, more than half expressed comfort, suggesting an intuitive ergonomic success. Others pointed to specific features: “light,” “stylish,” “snug around the hand,” and praised for offering multiple ways to hold it. One user indicated that the D grip “felt more easy to balance” when she shifted her weight, and gave her more grip options. For the cane tip and base, around 80% preferred a wider rubber bottom, citing improved balance and traction.

Further discussions highlighted social stigma and the importance of customization and sentimental value, cementing key priorities that will be incorporated into our final design. Three participants shared anecdotes about modifying their own canes, for example, about cutting the shafts, adding wrist straps, or improving rubber tips. Their language conveyed a sense of pride in making the device “theirs.”

Final Prototype

The final grip design was informed by further feedback, and stress, strain, and displacement simulations conducted on the two final grip prototypes. It is designed as a hybrid model of the two grip prototypes, providing a horizontal bar as in Grip A while incorporating design elements and geometry from Grip D. While the final grip remains less rigid than Grip D, it offers better stability than Grip A, while also accommodating to different holding styles that promote a neutral wrist position.

Engineering Analysis

We conducted Solidworks simulations to validate the design, applying 147 N downward and 25 N side forces. The grip withstands expected user forces without yielding, when applying force from both the side of the grip and the top. Further material studies validated our choice to use PLA, suggesting that generic PLA balances rigidity with practicality for prototyping.

Assembly & Component Drawings

Final Design

The final product consists of our cane design, a reversible shaft sleeve and 2 grip covers for customization and comfort.